How Hydraulic Starting Systems Work

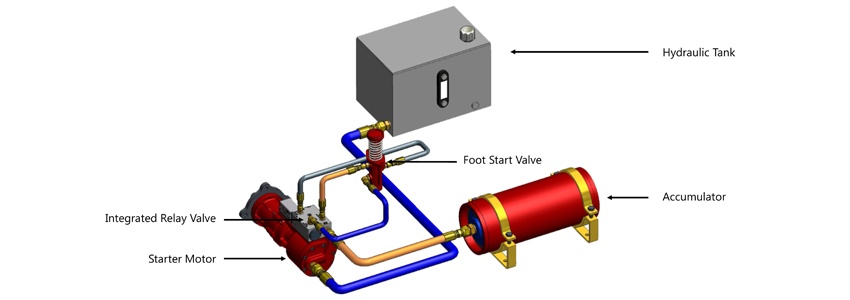

Hydraulic starting systems store energy in the form of hydraulic oil under pressure inside a piston accumulator. The oil is released by a manually operated foot valve or a solenoid-operated start valve.

Once released, the oil travels to the starter motor which engages with the engine’s ring gear and starts to crank the engine.

When the engine has reached firing speed the pinion gear is automatically kicked back by the ring gear.

Page 12-15 of our handbook offer a useful guide to IPU’s range of hydraulic starters – Click here to request your free copy

Recharging can be done manually using a hand pump, electrically using a hydraulic pump or even using the host machine’s on-board hydraulics.

- The starter motor engages with the engine’s ring gear and cranks the engine

- The accumulator stores energy almost indefinitely in the form of pressurised oil.

- The hand pump recharges the accumulator without needing an external power source.

Diagram of how hydraulic starting systems work

How the hydraulic starter motor works

-

-

- Oil pressure is taken from the pilot inlet port on the valve block to the start valve.

- When energised, this oil flows from the start valve back to the block and enters via the actuation port.

- This pushes the piston backwards, which moves the drive and pinion forward.

- When the pinion has engaged the ring gear, the piston uncovers a port on the block which allows oil to pass through to the start valve cartridge.

- Upon receiving this oil signal, the start valve cartridge opens up and allows oil to enter the starter motor and start rotating.

-