Fuel Polishing Systems – Diesel Defence

Fuel polishing systems are vital for diesel-powered emergency systems. They remove a critical point of failure: fuel contamination. Modern engines and fuel systems need clean fuel to run reliably. If left untreated diesel is under constant attack from water, microbial growth and solid particulates, even after cleaning. There is a solution. Diesel Defence units preserve your stored fuel to EN590 standards, greatly improving the reliability and dependability of your critical systems such as standby generators and fire pumps.

Our Fuel Polishing handbook offers an explanation of the importance of keeping your fuel clean – Click here to request your free copy

Diesel Defence: long term protection for your stored diesel

IPU supplies two families of diesel polishing system; the flexibility of our range means that we can service any tank size:

-

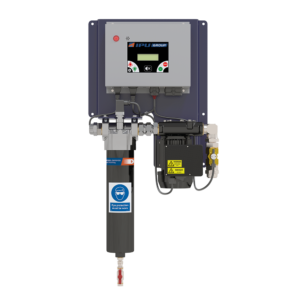

- Diesel Defence on-tank units are fixed location units that serve up to 3 large storage tanks., They are designed as ‘fit and forget’ solution – set them up once and they run unassisted month after month, year after year. The DDF2 to DDF6 fixed on-tank models even feature an integrated password-protected touchscreen controller.

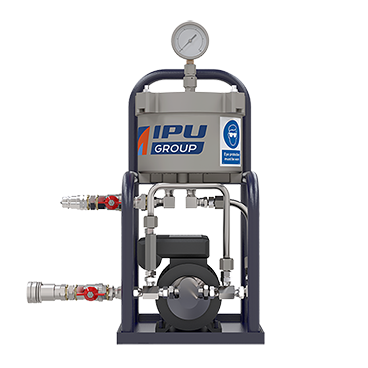

- Diesel Defence mobile buggies give you the flexibility to polish the fuel in numerous smaller tanks with a single device.

Product range – fixed units

| EKO with Kapture Technology | DDF1 | DDF2 | DDF3 |

|

|

|

|

| 50lp/m flow rate | 50lp/m flow rate | Up to 100lp/m flow rate | 150lp/m flow rate |

| 10,000l tank size | 10,000l tank size | 30,000l tank size | 80,000l tank size |

| View product | View product | View product | View product |

| DDF6 | DDF-MFR | DDF-HFR | Servicing |

|

|

|

|

| Up to 500lp/m flow rate | up to 50lp/m flow rate | 5000lp/m flow rate | N/A |

| 100,000l+ tank size | 1,000l tank size | Up to 5,000,000l tank size | N/A |

| View product | View product | View product | View product |

Product range – mobile units

| EKO Mobile | DDM1 | DDM2 | DDM3 |

|

|

|

|

| 10lp/m flow rate | 100lp/m flow rate | Up to 100lp/m | 150lp/m |

| 1,000l tank size | 5,000l tank size | 10,000l tank size | 30,000l tank size |

| View product | View product | View product | View product |

| DDM5 | DDM6 | Servicing | |

|

|

|

|

| 250lp/m | 500lp/m flow rate | N/A | |

| 50,000l+ tank size | 500,000l tank size | N/A | |

| View product | View product | View product |

Frequently asked questions

- What is diesel fuel polishing?

It is impossible to deny that “fuel polishing” is an odd phrase to anybody seeing it for the first time. While it has nothing to do with dusters and beeswax, it has everything to do with cleanliness. More importantly, it is a vital part of any standby power strategy.

Diesel fuel polishing is the maintenance process that stops water and contaminants infecting fuel while it’s held in storage tanks. It increases generator reliability and longevity.

By removing water, diesel bug and particulate contaminants from your stored diesel, IPU Group’s Diesel Defence systems ensure that your generators, pumps and plant keep running as long as you need them. It’s the protection your fuel system needs. Although you probably already have a programme in place to maintain the diesel engines that provide critical power to your facilities, the fuel that feeds them is often overlooked.

- What's the difference between polishing and cleaning?

Would you polish a dirty car? Obviously not. You know there’s a difference between getting mud off the paintwork and giving it a showroom shine.

The same is true for fuel conditioning.

If a fuel test shows that you have contaminated fuel you should have it cleaned through our ClearTank service. Your fuel with conform to EN590 and ISO4406 levels of cleanliness once the cleaning is complete.

But fuel doesn’t stay clean. Water enters it from a variety of sources. The diesel bug grows. Rust falls off the side of the tank. Polishing is the process that stops this causing problems. It keeps clean fuel clean.

Diesel Defence systems are not designed to clean dirty fuel. They only polish it. They use fine filtration to remove tiny particles and water molecules before they grow large enough to be a problem. A polishing unit that cleans heavily contaminated fuel needs regular filter changes. This is expensive, disruptive and unnecessary.

- Why are Diesel Defence systems better than standard filtration?

Diesel contamination has many causes. On-engine filters only clean fuel as it passes from your storage tanks to your generators. Although they can remove debris they do nothing to clear the causes of the problem that lurk in your fuel tank.

Unless the causes are treated, filtration systems will be under a constant attack and can become overwhelmed.

IPU’s polishing systems work at the tank, removing water, microbial growth (a.k.a. the diesel bug) and solid particulates (such as dirt, soot and rust) before they reach any part of your engine.

- Isn’t filtration a cheaper way to protect my generators and engines?

Relying on filtration has two shortcomings.

- Without treating its causes, contamination constantly bombards your filters. Clogged filters will starve your generators of fuel and risk a critical power failure.

- Filters need replacing. The more contaminants they have to remove, they more frequently they need replacing. This places a triple burden on your finances: the cost of the filters, the labour taken to replace them and the cost of the maintenance regime that checks their condition.

Removing the causes of contamination with a polishing system is the most cost-effective and efficient route to clean fuel and reliable power.

- How does fuel become contaminated?

In most European countries diesel contains 93% petrochemical diesel and 7% biodiesel. The biodiesel blend reduces the environmental impact of burning fuel. However, biodiesel contains water. It’s present when the fuel’s manufactured and biodiesels attract more water while they’re stored.

Water is the enemy of clean fuel:

- water is a contaminant in its own right.

- emulsified and free water encourages microbial growth (aka the ‘diesel bug’).

- water accelerates contamination from solids like rust.

Without proper maintenance diesel will degrade. It’s inevitable. Watch our short animation to understand exactly how fuel can become contaminated.

- IPU's three step fuel conditioning process

Diesel Defence is the third stage in IPU’s Fuel Conditioning Programme. The three-part programme is the simplest and most economical route to clean, dry, reliable fuel. It includes:

-

-

- DieselCheck Fuel Testing.

- ClearTank Fuel Cleaning

- Diesel Defence Fuel Polishing.

-

-

Video: protecting against fuel contamination

Our short video explains the four stages of the programme and how that can keep your diesel clean and dry:

Whether you store bowsers and drums under 2,500 litres or you manage a plant with over 500,000 litres of fuel, we have a Diesel Defence solution to support you.

IPU supplies two families of diesel polishing system

- Diesel Defence on-tank units are fixed location units that serve up to 3 large storage tanks. They are available to suit any tank size.

- Diesel Defence mobile buggies give you the flexibility to polish the fuel in numerous smaller tanks with a single device.