What is biodiesel?

Understanding ‘diesel’ is not as simple as it used to be. New fuel types have been developed in response to our desire to reduce the cost and environmental impact of diesel power. As with so many changes made with the best intentions, the introduction of biodiesel leaves many commercial and domestic users confused.

It is vitally important to understand the term ‘biodiesel’ in the context of your own industry, so for clarification on what it means, read the first few pages of our Fuel Conditioning Handbook. Click here to request your free copy

When biodiesel is added to the roster of diesel types – petrochemical diesel, ultra low sulphur diesel, red diesel, etc. – it does present a crowded and confusing landscape.

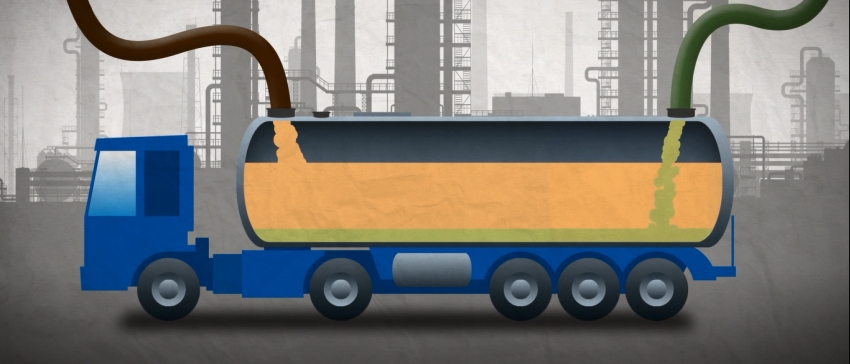

The diesel we buy in Europe is a blend of 93% petrochemical diesel and 7% biodiesel. Biodiesel – or FAME (Fatty Acid Methyl Ester) to give it its technical name – has been added to petrochemical diesel since 2011.

- What is biodiesel and how is it used?

Biodiesel is diesel fuel made from plants and other biological materials. The most common form of biodiesel is FAME (Fatty Acid Methyl Ester). However, biodiesel is rarely used in its pure form.

Biodiesel is added to petrochemical diesel to make the fuels we use. Different ‘B’ numbers are used to designate how much biodiesel the fuel contains: B7 uses 7% biodiesel, B20 uses 20% biodiesel, and so on. B7 biodiesel is currently used in the UK and Europe.

Diesel purchased in Europe, the United States, Canada and Australasia will almost certainly be biodiesel. Other parts of the world such as South America are starting to use biodiesel too.

The Middle East is still dominated by petrochemical diesel so, although they suffer less from water-borne contaminants like diesel bug, they do still encounter particulate contamination.

- Why does biodiesel present a problem?

For all its environmental advantages, biodiesel is more vulnerable to fuel contamination than petrochemical diesel because it has a higher water content. It contains more water when it leaves the refinery and because it is hygroscopic, it can attract even more water if it is stored badly.

Water is problematic in two ways: it can damage engines during the combustion process and it encourages the growth of microbial contamination (a.k.a. the diesel bug) in storage tanks.

When stored, biodiesel also suffers from particulate contamination even more so than petrochemical diesel. Rust, dirt, wax, sand, clay, asphaltines, microbial growth and colloid carbon all reduce the fuel quality.

IPU’s Diesel Defence fuel polishing systems combat particulate and water-based contamination.

Watch this video to learn more about fuel contamination:

A fuel conditioning programme addresses this problem. An effective programme includes four stages: testing, cleaning, polishing and stabilisation.

This next video shows exactly how our fuel conditioning program works and ensures your fuel is clean, dry and ready to use:

- Is contaminated biodiesel risk to me?

IPU serves numerous organisations that provide critical power to hospitals, government facilities, military installations, banks, data centres and other commercial sites.

When mains power fails these sites already face severe problems. They cannot afford any possibility that their backup power will fail too. Because biodiesel is so easily contaminated it is unquestionably a potential point of failure.

An effective fuel conditioning programme removes this risk.

Biodiesel’s specific characteristics have prompted leading engine manufacturers and fuel companies to issue best practice guidance for its storage.