Pearl Air Starting GTL

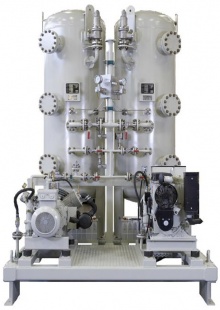

Air Start Package

IPU have supplied six complete air start systems for the Pearl GTL project in Qatar. The plant, a joint development by Qatar Petroleum and Shell, will process about three billion barrels-of-oil-equivalent over its lifetime from the world’s largest single non-associated gas field, which stretches from Qatar’s coast out into the Gulf.

The field contains more than 900 trillion cubic feet of gas, about 15% of worldwide gas resources and will produce enough fuel to fill over 160,000 cars a day.

The compressed air system was designed for primary starting of the CAT 3616 engines; driving generators which will supply the main power for Gas to Liquids plant during the construction phase, and which will later supply standby power for the site. The starting system was to be situated in Ras Laffan, Qatar and therefore had to be equipped to deal with temperatures up to +50ºC with high humidity.

The complete system comprised two stainless steel 1900 litre ASME VIII Div. 1 and ‘U’ stamped air receivers, storing air at 30 bar. The design featured a duty electric compressor and diesel driven standby compressor. All pipe work, valves and fittings were in stainless steel and all instrumentation and electric components were made to meet Zone 2 requirements.

IPU Starting systems can be designed to comply with Shell’s demanding DEP (Design and Engineering Practices) specifications in mind.

For more information contact a member of our Starting Sales Team on +44 (0) 121 511 0400